gas spring life test|gas spring system : importers Standard gas springs are rated for use between -20°C and +80°C. Special gas springs can be manufactured for use between -40°C and +100°C. Camloc use the “temperature . webVeja os resultados dos jogos da Santa Casa de Misericórdia de São Paulo, incluindo Totoloto, Euromilhões, Joker, Totobola e mais. Escolha a data e confira os números .

{plog:ftitle_list}

WEBJessica Nua. Jessica Rotinas Os melhores videos amadores de novinhas fazendo putaria com Jessica Rotinas nas cenas quentes do Kabine das Novinhas!

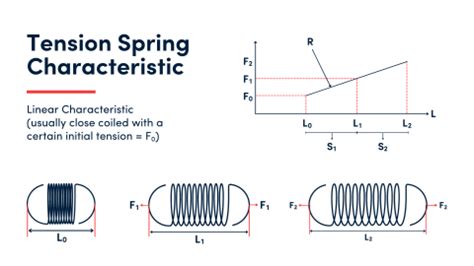

In order to design technical springs optimally for their intended use, the spring characteristics must be defined and tested. The spring charac-teristic curve illustrates the spring travel as a .A gas spring is a closed system which requires no further gas to be introduced to the system for it to operate once charged with inert Nitrogen gas and manufactured.The locked gas spring shall be locked in the mid-span state to test its locking force. The measuring speed of the spring life tester is 2mm/min, and the axial compression force .Standard gas springs are rated for use between -20°C and +80°C. Special gas springs can be manufactured for use between -40°C and +100°C. Camloc use the “temperature .

testing metal springs pdf

spring characteristics test

The general service life of SUSPA gas springs is between 10,000 and 100,000 double strokes (1x retraction and extension) depending on the type of gas springs. At SUSPA, the service life is .When choosing a gas spring for a particular application, it’s imperative to have a basic understanding of the workings and terminology used when specifying gas springs. This article offers recommendations and guidelines for different . There is a better way to get the best gas spring: Take an engineering approach to adding gas springs to designs, and use standard industrial gas springs as a starting point.

What is the expected life of a gas spring? When calculating the approximate life of a gas spring, one must first determine how much force the gas spring can lose before the user considers the .

The initial force of the gas spring can be calculated as the sealed area of the piston rod or the piston (depending on design) multiplied by the pressure inside the gas spring. The larger the . Gas springs as energy reservoirs. A gas spring's job is to make your life easy—and it does it by storing energy (when there's plenty available—usually when you're lowering something heavy) and releasing that .The gas spring durability test device can simulate actual work conditions of the gas spring in a swing mode, and therefore service life parameters of the gas spring can be measured more accurately. The invention discloses a gas spring durability test device which comprises a support, a swing arm, a supporting table and a drive device.

common rail cummins compression tester

how to apply gas spring

compressed air cylinder testing near me

Gas springs on the market are similar in appearance, only the difference in size or force value. Why the life test specifications are various from 10,000 times to 180,000 times. Following taking Peir’s gas spring as an . Need a constant force? Gas springs have got you covered!But how on earth do they do what they do?!We need some common ground to understand what's going on. .Output forces of a gas spring are factory-set to customer specifications. Each gas spring is pressurized to obtain the desired working force P1and dependent forces P2, P3and P4. As shown by the diagram in figure 2, when an external compressing force exceeds the extended force of a gas spring (P3), the rod compresses into the cylinder. The conventional process of testing spring life is time-consuming and expensive. Hence, a need was felt to establish a life-cycle test apparatus to eliminate the time constraints (i.e. it should test multiple springs at the same time) and to provide adequate and reliable data for plotting reliability of the operating life of springs.

When calculating the approximate life of a gas spring, one must first determine how much force the gas spring can lose before the user considers the gas spring too weak in the application. The time it takes to lose this amount of force is considered to be the life of the gas spring. All gas springs lose output force over time.

Gas Spring Testing by Metrol Springs Ltd. To see the complete range of Gas Springs see:http://www.metrol.comThe difference between the forces seen at the two extreme rod positions- named P1-force and P2-force respectively- is an important gas spring characteristic and called K-factor (IGS) or gas spring progression. When compared to mechanical springs, gas springs can achieve very low K-Factors, typically ranging from 1.05 to 1.8 (or %-80% progression).3 Stroke and ductility test: Measure the maximum and minimum stroke of the gas spring, and test its telescopic ability to ensure that it can work smoothly under different operating conditions. 4 Durability and life test: Evaluate the durability and life of the gas spring through long-term repeated operation tests to ensure that it .

50,000 life cycles each gas spring has passed the SGS test for 50,000-lifetime performance, with some exceeding 100,000 to 180,000 cycles. . salt spray test for more than 144 hours, the annual production volume is more than 5 million pieces, and 60% are exported.Shop 30+ types of Attwood Springlift Gas Springs made with bio-degradable oil. Attwood is one of the world's leading suppliers of stainless steel gas springs. . All springs pass the tough Attwood Salt Spray and a 30,000 cycle life test. Attwood springs come with support to ensure the proper spring for your specific application.The company can customize various types of gas springs. With various choices of gas springs and connectors, you're sure to find the right type and size. More than 100,000 fatigue tests to ensure the durability of each gas spring. Each batch of products undergoes strict life test, salt spray test and impact test to ensure great product quality.

gas springs explained

Gas springs provide controlled motion and speed for elements, such as lids and doors, that open and close. They typically rely on the fluid dampening of a gas such as nitrogen in the cylinder. Important performance specifications to consider when searching for gas springs include absorber stroke .

Compression gas springs manufactured in high volumes for cost-effective application solutions such as aid-lifting & counterbalancing. View our catalog! . Main features & benefits of our compression gas springs. Service life up to 125,000 cycles; Superior reliability in a wide range of environmental conditions;

Life Science. Manufacturing. Nuclear. Oil and Gas. Power Generation. Pulp and Paper. Renewable Energy. About Us. Certs and Standards. Acquisitions. Acquisition History. . including spring fatigue testing. Our experts test .

Reliability Testing Methods 1. Accelerated Life Testing. Purpose: To predict spring life under normal conditions by subjecting it to elevated loads or harsher environments. Procedure. Setup: Expose the spring to higher-than .Instructions for using a micro (C) series nitrogen gas spring test stand. Micro Test Stand. Charging and Analyzing. Charging Nitrogen Gas Springs. Instructions on how to charge nitrogen gas springs. Charging Nitrogen Gas Springs. Nitrogen Gas Booster System: DGB-150 .These test standards provide for an optimal installation of gas springs. After the service life tests are completed, only a minimum power loss from escaped gas is tolerated at SUSPA. However, the actual service life of a gas spring in application depends on many factors. That is why gas springs should be tested in the respective application .

SUSPA® is one of the world's leading manufacturers of gas springs. We offer you a large selection of lockable and non-lockable gas springs. Home; News; Online-Shop; Download . Gas springs are tested in our technical department on systems, test equipment and trial facilities: Linear test benches; Folding test benches ; Climate test chamber . This is a comparison test between the gas spring and a Gamo factory steel spring. The table below gives the velocity and extreme spread for each pellet with the steel spring and then with the gas spring. . I really don’t have much data on the service life of gas springs. They definitely do outlast a steel coiled mainspring, but you would .

rod and the static seal to the tube. Our gas spring seals improve the performance and service life of the gas spring and are engineered to operate reliably, with filling pressures of up to 180 bar. Superior seal design for optimum service life Gas spring seals need to offer a high degree of lexibility, working effectively in a wide range of .

compressed air leak test procedure

BEST GAS SPRING IN THE MARKET. NITROGAS’s gas springs offer the world’s most advanced technology, guaranteeing longer gas cylinder life than other products on the market. Nitrogas offers customers products that meet any test of approval, confirming the longer life of our cylinders 25 YEARS OF EXPERIENCE SPEAKS FOR ITSELF .A virtual measurement subtracts this variable from the displacement to create a “Corrected Spring Deflection,” which will artificially zero the deflection after reaching the free height. Test Control. Spring testing is typically performed using a monotonic test with an end-of-test criteria.

Any damage to the Gas Spring could affect safety and life of the product. The spring should be degassed and disposed of. The nominal stroke listed in the catalogue may be . Please see page 120 for gas spring test stands. X X X DO NOT MODIFY, MACHINE, DRILL OR WELD. X X X MAX. 80°C ALL METROL GAS SPRINGS are permanently marked on the

4. Our gas springs are designed for ambient temperatures of between -30 and +80°C. If possible, avoid intensive use at the extremes of this temperature range. Reducing/increasing ambient temperature also means a reduction/increase in gas spring force. 5. Gas springs are designed to handle axial loads. Avoid radial forces (lateral forces).Get lift supports, gas struts, springs, & more from Lift Supports Depot. Enjoy 1-on-1, personal service & a limited lifetime warranty on select lift supports! Look for our EXPRESS SHIPPING ICON for items that qualify for FAST delivery! FREE STANDARD SHIPPING SITEWIDE and 6.99 .An exercised spring moves in small complex ways that affect measurement, from the non-linear measurement of a bottoming-out conical spring, to the slight twist or tilt in a helical spring, or the behaviour of an extension spring end loop under tension, and the friction in holding or supporting a light torsion spring as it is worked under test.

Clique Para Compartilhar No Facebook(abre Em Nova Janel.

gas spring life test|gas spring system